In 1943 Thomas Watson, president of IBM was quoted saying:

I think there is a world market for maybe five computers.

Toothless was his prediction. Less than 6 decades later Forrester Research estimates that there are over one billion computers currently in use. That’s an error of a factor of about 200,000,000. Not bad for the CEO of a company that employs 435,000 people worldwide. So why was Watson’s prediction so shortsighted you might be asking yourself? Thomas looked at computers as a static technology. Computers were the size of homes, had a niche focus, tough to use and extremely expensive. What could be game-changing about that he probably thought?

BUT as you probably know, the beauty of the technological realm is that the tech world is “an object with perpetual motion and acceleration”. Just think of Moore’s famous Law – “the number of transistors in a dense integrated circuit doubles approximately every two years”.

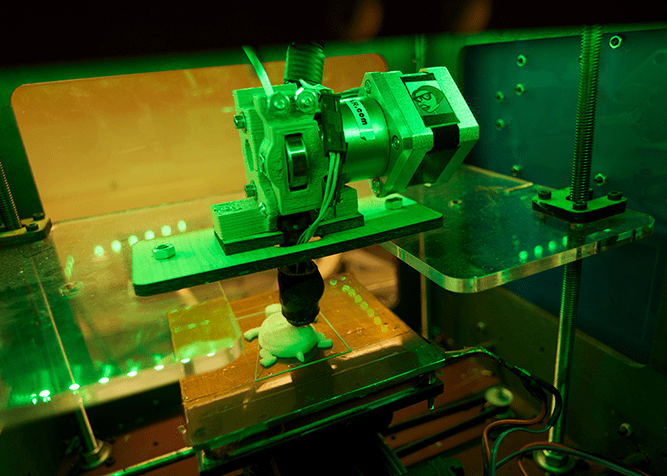

There are many out there that are saying 3D printing is not game-changing. They say 3D printing is slow, hard to use, limited in applicability and thus far, very far from “game-changing”. Whilst some of these critics hold a grain of truth, 3D printing technology is evolving at the “speed of light”. 3 decades after Chuck Hull created the first additive process (in other words, 3D printing), what is in stock?

SUPERDRACO – Reaching Space with 3D

Do you think 3D printing objects can propel planes? If you think yes you are actually quite right. 3D printing technology is not only being looked into by Boeing and Airbus, rather also being used to create the engines of the Dragon V2 space capsule. In May 2014 Elon Musk, the founder of SpaceX surprised us with a fully printed rocket engine. Made of the inconel superalloy, thanks to 3D printing technology, SpaceX was able to create an engine in less time, with superior strength, ductility, fracture resistance and a lower variability in materials properties. So when anybody tells you 3D printing produces weak objects refer to SuperDraco.

WINSUN – Design and Print your own house

Imagine you could design your own house using 60% the material, 4 times less time and for a fraction of the cost? This is what Winsun, a Chinese company has achieved. Winsun Decoration Design Engineering Co. has the technology to print over 10 homes from recycled material in a day. How do they do this? They use a 20 feet tall, 33 feet wide and 132 feet long structure that host a 3 dimensional mobile 3D printer. This 3D printer moves according to the design inputted to fabricate the house desired by adding layers of a patented “ink”. What is most staggering of all is that this patented “ink” is flexible, self-insulating, and resistant to earthquakes. As of now Winsun has around 50,000 orders and is expanding its technology.

VOXEL 8

Have you ever considered creating your own quadcopter, or any other electronic equipment? Thanks to Harvard Professor Jennifer Lewish and her team, Voxel8 allows us to do so. Voxel8 has invented a 3D printed ink that enables users to easily wire together chips and other electronic components within their 3D printed objects. This allows a degree of design freedom for electronics unconceivable in the past.

ORGANOVO – bioprinting

Organovo is the company at the forefront of Bio-printing. What is BioPrinting? BioPrinting enables generation of several kinds of tissues. Examples include skin, bone, cartilage, trachea and hear tissue. As of now the challenge is how to create critically functional tissue structures towards the generation of fully functional replacement organs and tissues, such as aortic heart valves.

So to all those doubting 3D printing, it is true that 3D printing can improve. Yet, it has and will continue!

Feature Image: Keith Kissel